The DARROW project

From waste to resource

Global challenges such as climate change and water scarcity have changed our view of wastewater: Due to its complex blend of chemicals, nutrients and metals it is now considered a valuable source of clean water, nutrients and energy. This has triggered a paradigm shift in the wastewater sector. Wastewater treatment plants are now considered water resource recovery facilities seeking to obtain the most value from wastewater.

Accelerating sustainable water resource recovery

Water resource recovery facilities can produce clean and safe water, recover nutrients and produce energy. Despite the extensive potential of wastewater, only a small portion of total wastewater produces is currently exploited for resource recovery. Increasing the feasibility and efficiency requires new and better technology. The EU-funded project DARROW will provide data-driven solutions to make the most of our wastewater.

Save energy

Reduce Waste

Reduce Greenhouse Gas Emissions

Contribute to a circular economy

Start date:

1st September 2022

End date:

28th February 2026

Budget:

3 531 446,25€

8 partners from 4 EU countries:

Spain, Belgium, Germany, and the Netherlands

DARROW's goals

Leveraging AI tools to make water resource recovery facilities more sustainable. What does this mean exactly?

Our approach

DARROW will develop and validate an innovative, modular, and flexible AI systems to optimise the performance of wastewater treatment plants by making them more autonomous and more energy efficient.

DARROW's demonstration

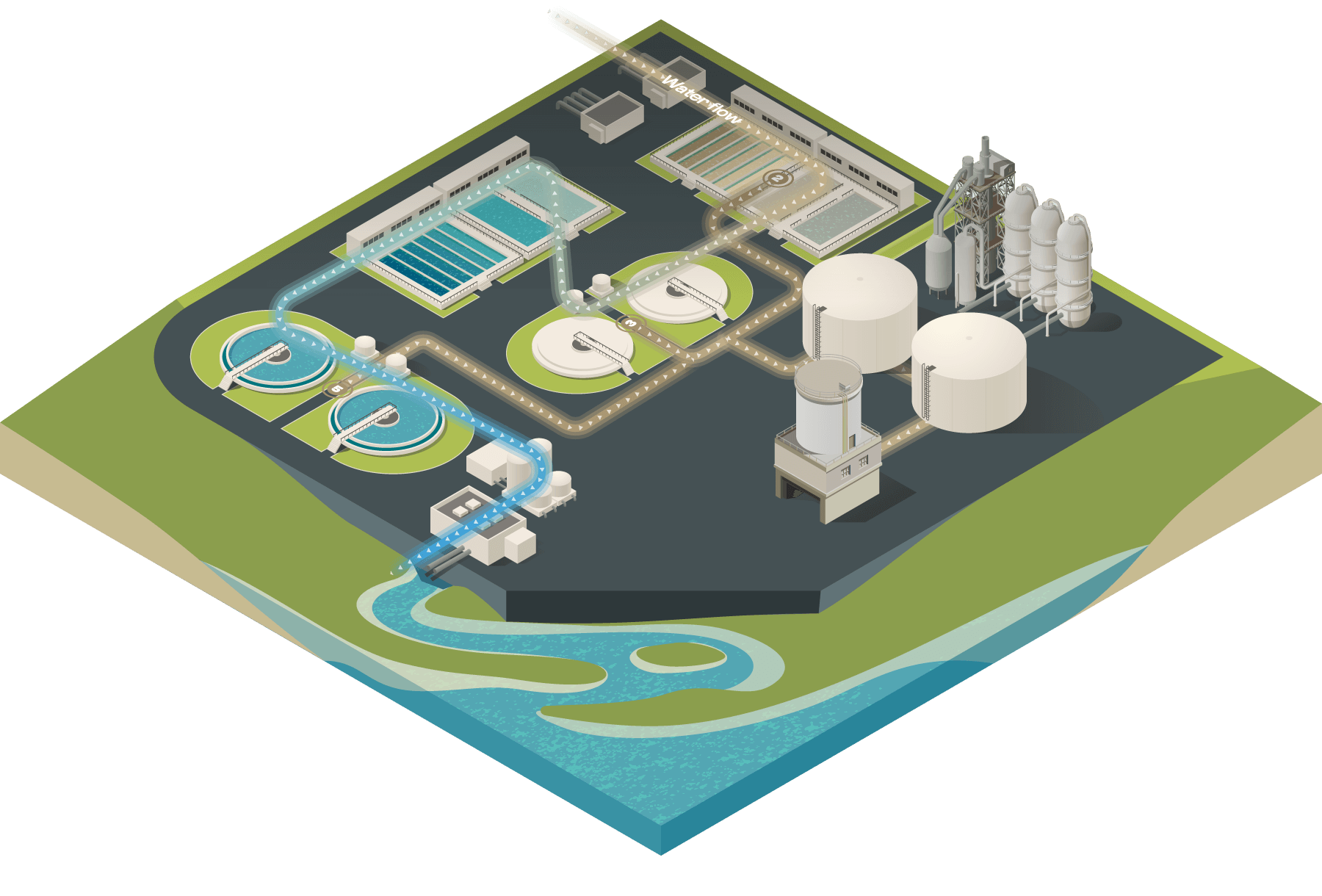

The Tilburg wastewater treatment plant

The Tilburg wastewater treatment plant is one of the largest water resource recovery facilities in Southern Netherlands. It purifies 10,000 cubic meters of wastewater daily from Tilburg, Udenhout, Berkel-Enschot, and Biezenmortel. This crucial process ensures the release of clean water into the Zandleij river, contributing to the region’s environmental well-being.

The Tilburg plant will serve as a demonstration site for the DARROW solution. The developed tools will be implemented and tested there. With its innovative AI solution, DARROW aims to optimise resource recovery from the secondary treatment and anaerobic digestion processes, while guaranteeing overall plant efficiency.

The water line in Tilburg comprises three parallel trains featuring primary clarifiers, biological treatment, chemical removal, and secondary clarifiers. The sludge line incorporates a Cambi unit for sludge cracking, anaerobic digestion, and Anammox and Phospac units for side-stream treatment. Additionally, the Tilburg plant houses the Energy Factory Tilburg, dedicated to digesting and treating all sludge from Waterschap De Dommel for biogas production.

The water line in Tilburg comprises three parallel trains featuring primary clarifiers, biological treatment, chemical removal, and secondary clarifiers. The sludge line incorporates a Cambi unit for sludge cracking, anaerobic digestion, and Anammox and Phospac units for side-stream treatment. Additionally, the Tilburg plant houses the Energy Factory Tilburg, dedicated to digesting and treating all sludge from Waterschap De Dommel for biogas production.

From inflow to outflow: An interactive guide through wastewater treatment

Curious to learn more about wastewater treatment? Explore the intricacies of the process with our interactive infographic below. Hover over key components to gain insights into the purification and energy production processes. The inflowing wastewater (1) first passes through a grit chamber (2) to remove heavy solids. Then, in primary treatment (3), large particles settle out. This is followed by secondary treatment (4) where microbes break down organic matter. Clarifiers (5) then separate remaining solids. The sludge line (8) carries these solids to anaerobic digestion (9) to produce biogas. The gas can be used to generate electricity (11). The sludge is then dewatered (10) for disposal. Meanwhile, UV disinfection (6) kills pathogens in the treated water before it is released (7) into the environment.

- 1 - Influent1

- 2 - Grit Chamber2

- 3 - Primary Treatment3

- 4 - Secondary Treatment4

- 5 - Clarifiers5

- 6 - UV disinfection6

- 7 - Effluent7

- 8 - Sludge line8

- 9 - Anaerobic digestion9

- 10 - Dewatering10

- 11 - Power generation11

1 - Influent

The untreated water that enters into a wastewater treatment plant.

2 - Grit Chamber

A chamber or tank in which the influent wastewater is slowed down so that heavy inorganic solids such as sand, metals, and plastics, can precipitate and be removed.

3 - Primary Treatment

The first stage of the wastewater treatment process. At this stage, mechanical methods such as filters and scrapers are used to remove solid pollutants.

4 - Secondary Treatment

The second stage of the wastewater treatment process. At this stage, biodegradable components are removed.

5 - Clarifiers

Settling tanks used to sediment solids contained in wastewater. Collected sediments are removed in the form of sludge. Clarified water from the top is removed separately.

6 - Ultraviolet disinfection

Ultraviolet light is used to kill bacteria and other microorganisms as a final treatment step.

7 - Effluent

Treated wastewater that flows out of a wastewater treatment plant and is returned to the water cycle.

8 - Sludge line

Semi-solid material that is produced as a by-product during the biological treatment of industrial or municipal wastewater

9 - Anaerobic digestion

Microorganisms break down biodegradable organic matter contained in wastewater to produce biogas and inert sludge.

10 - Dewatering

The process by which water is removed from the sludge. The results is dry and compressed sludge, known as sludge cake.

11 - Power generation

Biogas released during the anaerobic digestion is used to generate electricity and heat.

Wastewater treatment plants generate a wealth of data. Understanding these different types of data is key to leveraging AI for data enrichment and augmentation to ultimately improve the wastewater treatment process. Our infographic below shows the types of data a wastewater treatment plant produces.